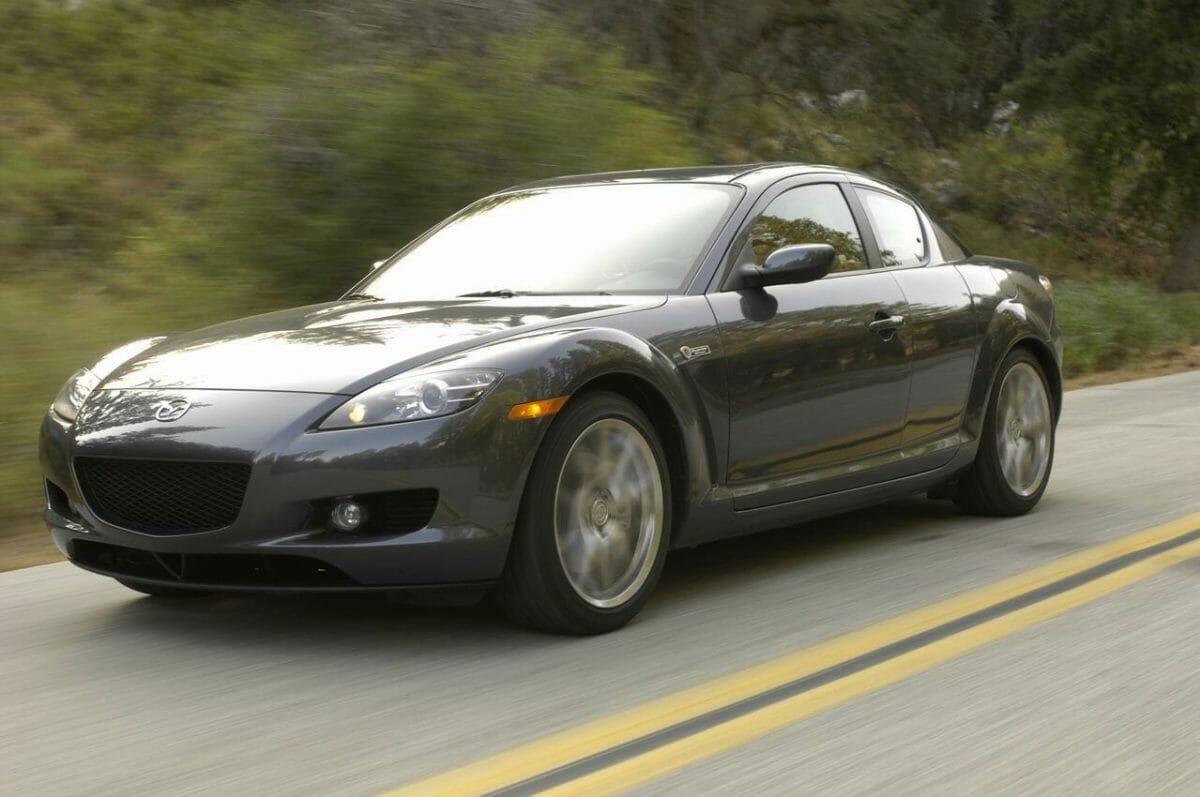

Mazda’s RX-8 is a well-balanced sports car with great handling. Here we review its engine in detail.

Despite its legendary motorsport heritage, the Mazda RX-8 engine does not inspire the same lust or cult following as its predecessor. This is due to the reliability issues and arthritic power output of the Mazda RX-8 engine.

This article will cover the ins and outs of Mazda’s 13B MSI powerplant and how changing emission standards relegated the rotary engine to history books.

History of the Rotary Engine

The original rotary engine was designed in 1954 by a German engineer named Felix Heinrich Wankel. He did this to provide an alternative to the traditional internal combustion engines with fewer vibrations. To accomplish this task, he started from scratch with the design. In the end, Wankel created something completely new named the DKM54 rotary engine.

Instead of a single or multiple pistons moving up and down, the “Wankel” engine uses a triangular-shaped rotor that spins on an eccentric shaft. This allows the engine to be very balanced, compact, and reach incredible revolutions per minute.

In 1956, an engineer named Hanns Dieter Paschke revamped the design to make it more cost-effective to produce, and that was when the modern rotary engine was born. The new KKM57P design would essentially remain on the shelf until the late-1960s. That is until Japanese auto manufacturer Mazda came poking around looking for an engine for their new model, the Cosmo.

Rotary Engine: How it Works

Simply put, the rotary engine is a triangle-shaped rotor that spins inside an oval housing. Each rotor has three combustion chambers, one for each side, and is housed in between a pair of plates to create a closed chamber. Rotary-style engines come in a single rotor form to the Le Mans-winning four-rotor engine.

When the ignition is turned, power is sent to the starter and mechanically forces the engine to turn. Starting at the top left of the housing, air and fuel are drawn in through a slot cut into the rear plate.

As the rotor turns, the mixture is compressed as the geometry inside the chamber changes. Once the mixture reaches around the 2 o’clock position, two spark plugs fire. This ignites the mixture, forcing the rotor to continue to rotate clockwise. After the combustion stage, all the gasses are forced through an exhaust port located under the intake manifold.

Unfortunately, besides making a cool noise, the only thing the rotary is efficient at is consuming fuel. It is not even good at burning the fuel it consumes.

Historically, this the reason for its poor fuel economy and emissions. Even with two spark plugs igniting the mixture, so little fuel in the chamber is burnt that tons of its vapor end up in the exhaust system. This is why RX-7s and other rotary-powered cars spit huge flames at hard gear changes. The vapor in the system builds up over time and under heavy load combustion is still happening as it enters the exhaust.

This ignites the fuel vapor in the system shooting a huge flame out of the tailpipe.

The basic design of the rotary engine would remain the same for many years. In the 1980s, changes came along as technology had advanced, like fuel injection and turbocharging. This brought huge power gains to the rotary engine and allowed the low displacement RX-7 to flourish in motorsport against traditional piston engines.

First-generation Mazda RX-8 (2002-2009)

The original Mazda RX-8 was a large departure from the last generation RX-7. What was once a low, two-seater sports car with the heart of a turbocharged weedeater, now had seating for four and rear cat flap doors.

On top of the passenger accommodation improvements, the RX-8 is pleasant to look at and handles beautifully. Unfortunately, the styling was not all they changed. The infamous fire-breathing 1.3L twin-turbocharged 13B-REW had been replaced with a new naturally aspirated 13B-MSI.

The new Renesis engine was still a 1.3L rotary but the turbos were gone and changes were made to how the exhaust housing worked. Instead of a large spherical port like the old models, the Renesis had a slot cut into the housing similar to how the intake plate works. This resulted in mild torque gains down low and improved emissions but lackluster performance.

Without the assistance of forced induction, the new engine only produced 189hp in 5-speed form. That is a rather pathetic amount when looking at the outgoing FD RX-7’s 261 hp. Not to mention, most RX-7’s made well over 300hp but were advertised at a lower figure to dodge a Japanese law limiting horsepower.

Attempting to improve fuel consumption on a notoriously dirty engine, Mazda raised the compression ratio and ditched the turbos because more air means you need more fuel. A low initial power figure is normally not an issue with aftermarket modification but the RX-8 engine does not handle force induction well.

Unlike the older 13B-REW that practically laughs at insane boost pressure, the 13B-MSI starts to come apart at the seams.

Second-generation Mazda RX-8 (2009-2012)

In 2009, Mazda refreshed the RX-8 with subtle styling changes and an upgraded suspension. Improvements were made to the lubrication system, including a stronger oil pump and more oil injectors to help with seal wear.

A new catalytic converter was installed to help with the premature failures as well as more robust ignition coils.

All these improvements helped to grow the power output to 212hp in sport trim and all models had the gear ratio slightly lowered to improve acceleration. These upgrades proved to be too little too late and didn’t do much to help Mazdas sales numbers.

In 2010, the RX-8 failed the new European emission regulations and was pulled from that market entirely. Mazda continued to produce the RX-8 in Japan until 2012 when the company pulled the plug altogether.

In recent years, Mazda has patented several prototypes of rotary engines that run on alternative fuel. Hydrogen seemed to show the most promise but the project was short-lived. With ever-increasing emissions regulations, Mazda has yet to find a viable use for the rotary engine moving forward.

Rotary Engines: Common Problems

Traditionally, rotary engines are known for flame-spitting horsepower, not reliability but the Renesis is particularly bad. Some major problems were addressed in the second generation but the solutions Mazda came up with only acted as a Band-Aid.

Most of these so-called solutions just make problems show up later. Here are a few common issues you can encounter with the Mazda RX-8.

- Carbon Build-Up: The changes made to the exhaust port cause the gasses to make a hard turn before entering the extractors. Over time, carbon created from burning fuel slowly builds up on the exhaust port. As the carbon accumulates in the passage, it slowly strangles the engine. Other issues like failing ignition coils can speed up this process and, like most issues with a rotary engine, you have to completely disassemble the motor to repair it.

- Oil Consumption: It is common knowledge that rotary engines are notoriously oil-thirsty due to the engine design. The only way the rotor and housing are lubricated is when oil is being injected into the chamber. Since everything is contained in a single cavity, the oil must be constantly injected into the combustion chamber to lubricate the seals. As parts like the apex seals and side seals wear, this consumption will get worse and leads to other issues. Unfortunately, there is no way around this unless you rebuild the engine. The RX-8 has to burn oil to function so make sure to always keep spare oil in the trunk.

- Catalytic Converters: When rotary engines were originally thought up emissions were of little concern. The design of the engine requires oil to be consumed and it directly leads to premature wear of the catalytic converter. This is because the excess oil being burnt creates more contaminants that need to be collected by the converter. Symptoms of a bad catalytic converter include poor gas mileage, loss of power, and overheating. Replacement of the converter will remedy the issue temporarily but excessive oil consumption is the root problem.

- Loss of Compression: The main reason scrap yards around the world are littered with Mazda RX-8’s is compression loss. Changes to the rotor itself caused the Renissis to have more relaxed tolerances than the older rotaries. The apex seals sit at the point of each rotor and seal each side from the next. Side seals are thin pieces of metal that ride against the walls of the chamber and are the equivalent of piston rings. All of these seals are vital in keeping the different chambers separate, insuring compression. As the seals wear, the pressure in the chambers begins to leak out. This causes loss of power and leads to excessive oil consumption. As this continues to get worse, your RX-8 will eventually not run at all, because it can no longer compress the fuel mixture enough for ignition. The only way to remedy this issue is to completely rebuild the engine. This total overhaul usually costs more than the vehicle is worth and means the end of the road for the car.

With all that being said, the Mazda RX-8 is an attractive-looking car with an even more attractive price tag. These cars can be picked up for pennies when stacked up to comparable vehicles but finding a reputable rotary specialist to make it all better is getting harder. If you manage to find a good running RX-8, it will likely be wonderful to drive and inspiring to look at as long as it lasts.

Photos: Mazda